In every home, office or company one can find at least a couple of PET bottles. They may be filled with water, vinegar or oil. Thus, the production of such bottles should be quick and organised in such a way so as not to generate high costs. Modern machines are necessary here.

The use of PET bottles

PET bottles are used in many different branches. We can buy juice, water, drinks, milk, oil, ketchup or spirits in PET bottles. The bottles also enable us to keep cleaning products and household chemicals safe.

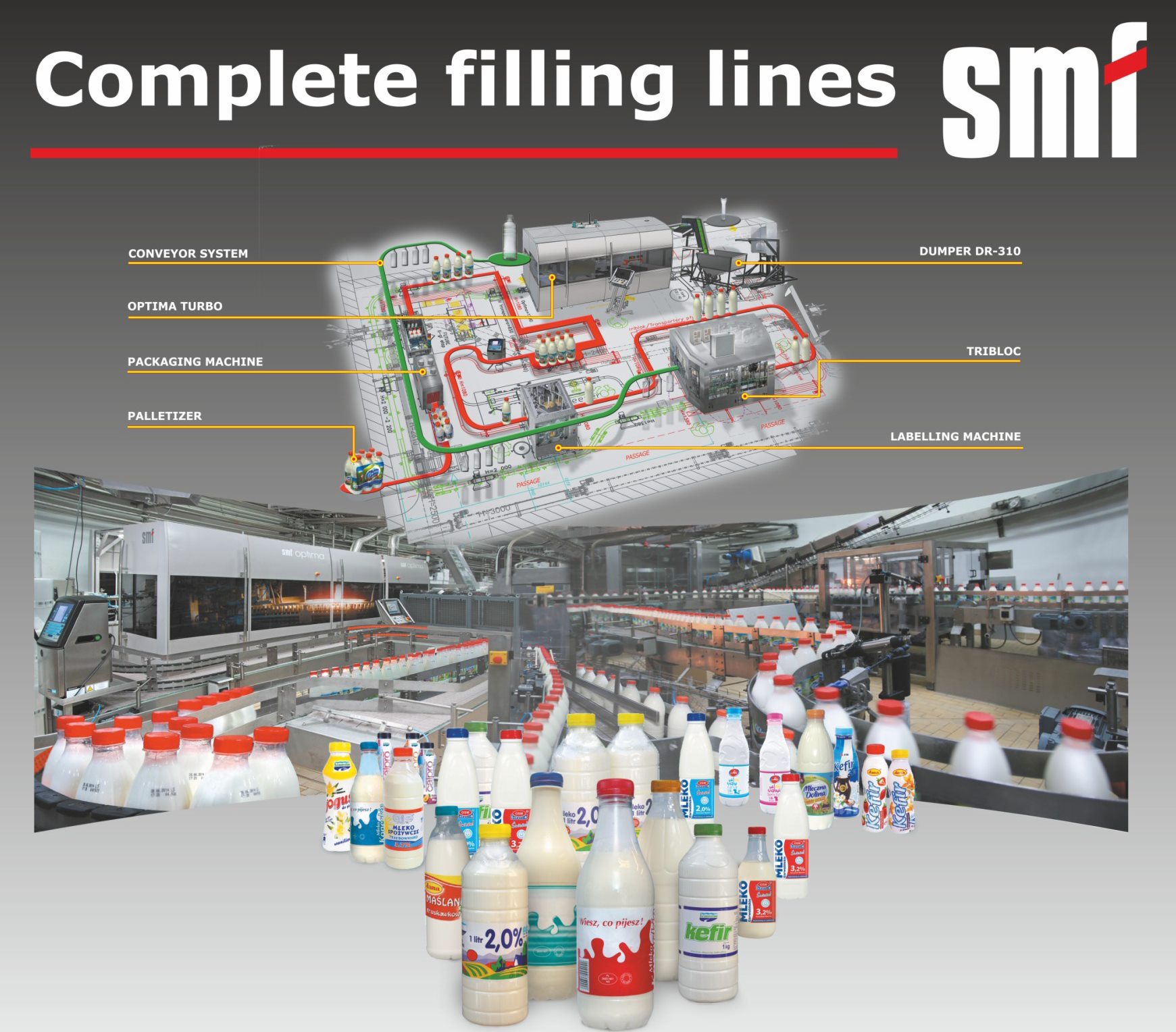

The production of PET bottles: SMF

As already mentioned above, PET bottles have wide applications. Therefore, their production should run quickly and efficiently, hence the need for high quality machines. Such machines are offered by the SMF company, available on the market for more than 30 years. In its offer one can find machines used for manufacturing packages for:

- water, carbonated drinks

- milk

- oil, vinegar

- spirits, beer

- household chemicals

The production of PET bottles: TOP 3

Among the machines used for producing PET bottles which are worth mentioning we can distinguish models, such as:

- Optima 16: a modern and efficient 16-cavity blower. This model is suitable for the production of PET bottles with a capacity from 200 to 2,000 ml, including embossed and square bottles. Within one hour, the machine is able to manufacture up to 28,000 bottles. Advantages? Solid construction, high quality components, energy-saving system for plasticising preforms, compact dimensions. The machine is recommended, among others, for the production of water bottles.

- Optima 10: a machine designed for the production of PET bottles with a capacity from 200 ml to 600 ml. The model is equipped with components made by renowned brands, such as, for example: Mitsubishi, Eaton, Lutze, Phoenix or Allan Bradley. Worth noticing is also the energy-saving system for plasticising preforms.

- Optima 8: the machine achieves efficiency of 14,000 bottles with a capacity of 500 ml produced within one hour. Its advantages include compact dimensions, energy-saving system for plasticising preforms and high quality components. The machine is recommended for the production of bottles for milk and dairy products, edible oil, spirits and carbonated drinks.

Summary

PET bottles are widely used, especially in the food industry. For this reason, their production must go smoothly and in an economical way. Among the recommended machines, we can distinguish the following models: Optima 8, Optima 10 and Optima 16 manufactured by SMF.