Robotic automation enables remote support possibilities that significantly reduce downtime and address geographical constraints, says Yaskawa Southern Africa Managing Director, Andrew Crackett.

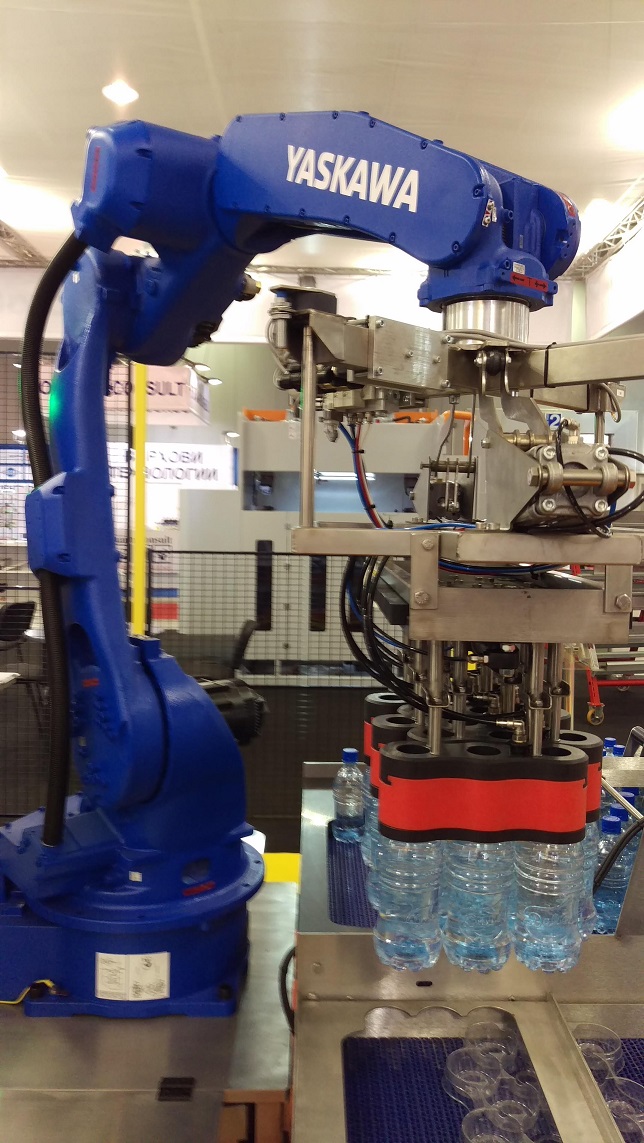

Conventional palletisers have been around for over 50 years. While they continue to be operational in many factories around the world, their modern counterparts – robotic palletisers – are solving issues that seemed impossible before.

Whether it’s the need to conserve floorspace or to make workplaces safer and better regulated, robotic automation has numerous benefits that other technologies struggle to match in the long run. One of the most appealing factors is that it actually pushes factories towards a more innovative and forward-thinking future. At times, this doesn’t even require everyone to be in the same time zone to collaborate.

Remote support technology excites a world leader in robots like Yaskawa. A recent success story is the implementation of palletising robots at Nile Breweries, a subsidiary of ABInbev in Uganda.

As the leading beer manufacturer in the country, Nile recognised that its equipment had aged and needed to be replaced. A tender was put out where numerous suppliers from around the world submitted their solutions and suggestions. A team from South Africa immediately stood out, thanks to the unique offering of Schullpak partnering with Yaskawa Southern Africa partnering with Productive Engineering.

“What gave us the edge was that we were the only submission that proposed robots,” says Director at Productive Engineering, Sean Irwin. “Everyone else proposed high-level palletising and depalletising solutions. Yet, Nile wanted to move into the world of robotics with all-new equipment, and decided we had the offering that would truly move its operations forward.”

With both Productive Engineering and Yaskawa Southern Africa being based in South Africa, you’d anticipate there would be logistical challenges in providing technical support to Nile. Especially if the team would need to fly out to Uganda to program the robots or deal with any technical-related queries.

However, there’s a reason that Yaskawa is renowned for providing unmatched after-sales support on the African continent – and that’s because it isn’t afraid to use technology to solve problems.

“We’re able to fully program the robots on site or remotely,” Irwin explains. “Additionally, we monitor the system remotely to see what’s happening in real time. If there is an issue, we’re able to log into the system and identify where the robot stopped working and why. This enables us to address the issue immediately or identify what needs to be done to reduce the downtime of the robot.”

Every business wants to reduce its downtime and increase productivity, so remote services that can adjust programming or even identify issues as and when they happen to make a significant difference.

“It’s part of Yaskawa’s philosophy to take full responsibility for a design or installation,” Crackett says. “We provide support on all aspects of the robot. Plus, our highly skilled team is available 24/7 for our customers, and we’re ready to answer any questions or impart our technical knowledge. At the end of the day, we want to help our customers ensure that they keep the productivity flowing.”

When it comes to palletising, robots are not just changing the landscape through turnkey solutions. Instead, it’s making it possible to control a factory’s production line from anywhere in the world. Now that’s real innovation.

About Yaskawa

Founded in 1915 by Keiichiro Yaskawa, Yaskawa is one of the largest manufacturers of industrial robots, with over 400,000 robots installed worldwide. Since 1991, Yaskawa Southern Africa has installed in excess of 2,500 Yaskawa MOTOMAN robots in the automotive, manufacturing and packaging industries in South Africa. As an industry leader, Yaskawa offers turnkey system solutions to a multitude of industries and 24/7 countrywide robotic support.