By Ella Teperi, General Manager, Market & Financial Analysis, Decarbonisation Services at Wärtsilä Energy

In African countries, particularly those with a well-developed industrial sector, a significant portion of energy production may come from the industry’s own power plants. This is especially true in countries where the reliability of the grid is low, and industries rely on self-generated power to ensure a stable energy supply. In this article, we are offering insights into our approach in supporting energy-intensive industries to optimise the use of renewable energy and reach their decarbonisation objectives.

In Africa, just like anywhere else, energy-intensive businesses are under great pressure to decrease CO2 emissions as they continue to compete in the global marketplace. Wärtsilä knows more about this than most: many of our mining and industrial partners in Africa operate their own microgrids, either from choice or necessity. They want to deploy renewables but need to do it efficiently and economically. Managing power intermittency and dispatchability is not a simple task, and most businesses struggle to make the most of hybrid power configurations. We will demonstrate how renewable balancing can not only reduce the CO2 emissions of operations, but also ensure overall system reliability and lower the cost of electricity going forward.

Making the most of your assets

Each industrial site is unique, there is no such thing as one size fits all when it comes to decarbonisation. There is a whole range of constraints, conditions and variables that are specific to each operation, site, and facility. And yet, there is one central question that everyone must answer to solve the decarbonisation challenge: how can I maximise the integration of renewable energy whilst ensuring reliability of supply and competitive energy costs?

When adding renewables and intermittency into grids, managing the increased complexity that inevitably ensues in a smart way becomes critical. Avoiding curtailment, managing reserves, and optimising the fuel consumption of thermal assets are the key elements that will get you further along the decarbonisation process. At an early stage, advanced power system modelling will help understand the impact of different operational profiles, figure out the optimal power generation strategies and leverage the benefits of dispatch optimisation.

Optimising your energy generation strategy

The optimal power generation strategy must reconcile three key objectives that are often considered contradictory. The first goal is to maximise renewable energy generation to lower CO2 emissions. The second is to guarantee that the supply of power is steady and reliable. Thirdly, to ensure that the total system cost remains competitive. Fail to achieve any of these goals, and your entire plan will tumble.

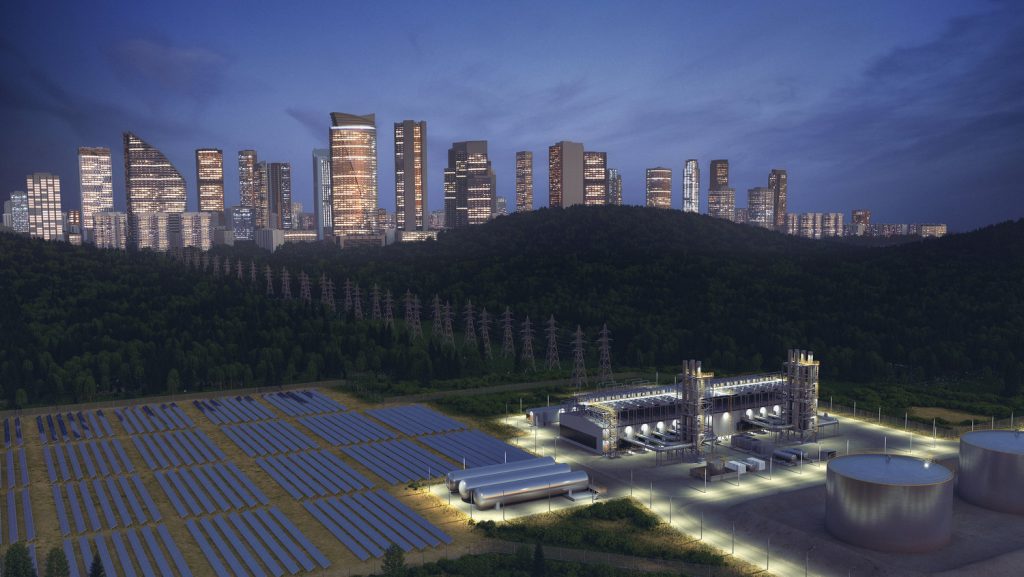

This is why smart decarbonisation strategies involve a holistic view over the entire microgrid, optimising the mix of renewable energy for baseload power, backed by energy storage and balancing engine technologies for dispatchable power.

While wind and solar power can offer emission-free energy at lower costs than fossil fuels, their intermittent nature adds uncertainty into the system. Adding renewables to your asset fleet will therefore require changing the way power balance is managed in order to ensure reliability, minimise the curtailment of renewables, and reduce the fuel consumption of thermal assets. Flexible power must be available to ramp production up or down at the same rate that wind or solar production fluctuates, but also to match the fluctuating energy demand in real time.

Flexible engine power plants and energy storage systems (ESS) can work together to support renewables integration. Both energy assets can react quickly and efficiently cope with multiple daily start and stops. ESS ramp extremely quickly, while engine power plants generate flexible, reliable power also during periods with low renewable generation and offer the advantage of being able to run on different fuels, from natural gas and liquid fuels or biofuels today, to locally produced hydrogen and its derivatives tomorrow as they become competitive and broadly available.

Thanks to this multi-fuel capability, not only do engine power plants provide a great hedge against fuel supply risk, but they are also the ultimate “future-proof” technology for decarbonisation. Gas engines can already run with 25% hydrogen blend without major modifications. We anticipate that a few years from now engines will be capable to run entirely on green fuels like hydrogen to reach 100% renewables and net-zero.

An intelligent energy management system (EMS) enables seamless operation of any mix of power assets. Wärtsilä’s state-of-the-art GEMS Digital Energy Platform utilises real-time data, renewable forecasts as well as machine learning algorithms, to optimise the dispatch of dynamic generation assets with speed, instead of applying a rigid rule-based model. GEMS’ optimisation and control capabilities enable reliability, minimised emissions, and reduced costs.

Decarbonisation is a journey, not a destination

For companies to remain competitive, their decarbonisation process must be based upon three pillars : emission reduction, competitive cost, and reliability. To get this done, the journey to net-zero for mining and industrial businesses in Africa cannot rely on a single solution. It is a long-term, future-proof plan that involves a data-driven management of energy assets.