Robotic logistics are the future of supply chain management, according to Yaskawa Nordic Sales Director Lee Moulder. In 2018 American companies spent approximately $1.5 trillion on […]

Tag: Yaskawa robots

Palletising Robots: Changing How Breweries Stack and Pack

Robotic automation enables remote support possibilities that significantly reduce downtime and address geographical constraints, says Yaskawa Southern Africa Managing Director, Andrew Crackett. Conventional palletisers have been around […]

Robots in the Workforce: No, the Machines Aren’t Taking Over

Robots aren’t here to replace humans, but to create a human-machine collaborative model for a more efficient and productive way of operating, says Yaskawa Southern […]

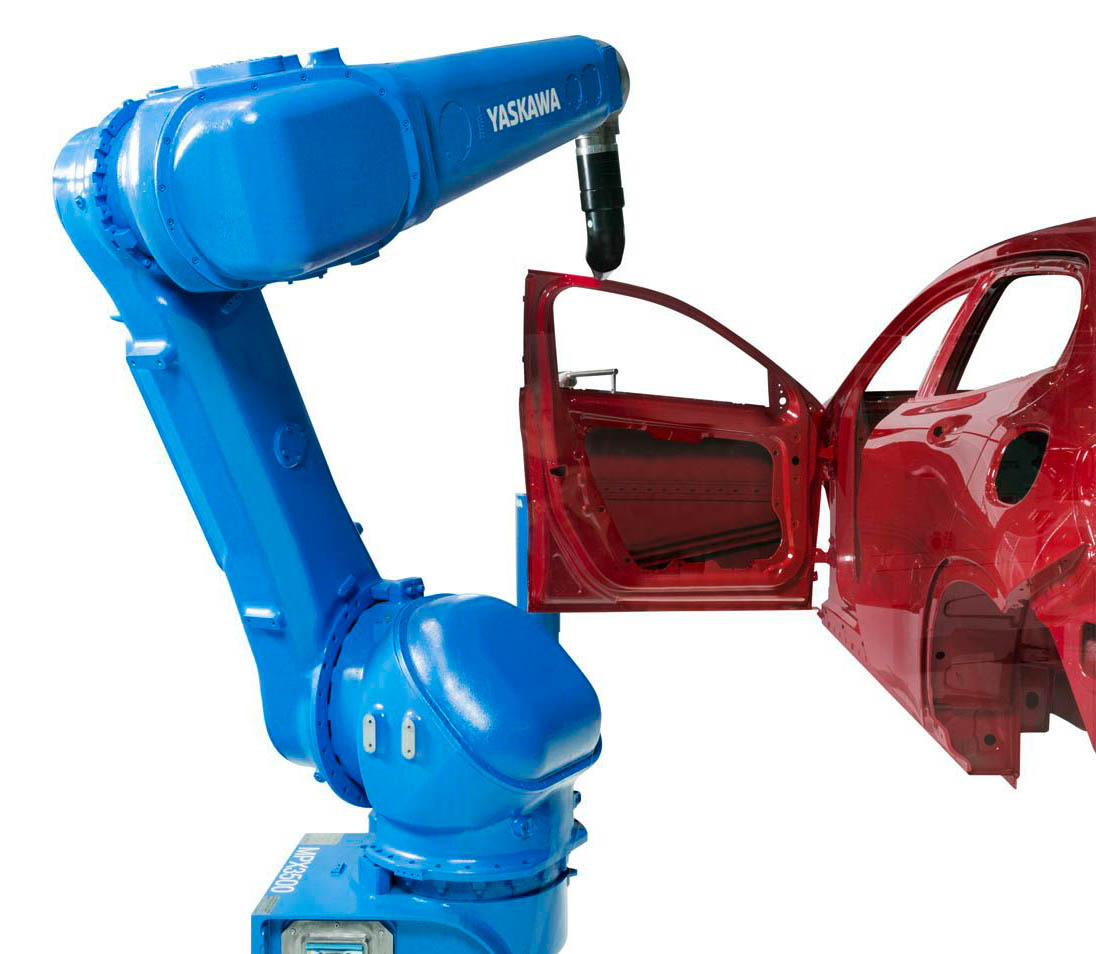

The Role Of Painting Robots

For a long time, the most common form of industrial painting required the use of human specialist coating teams, and typically, these jobs included the […]

The Role Of Pick And Place Robots

In years gone by, manufacturing processes consisted of a line of workers being solely responsible for all the material-handling functions. Whether it was assembly, picking […]